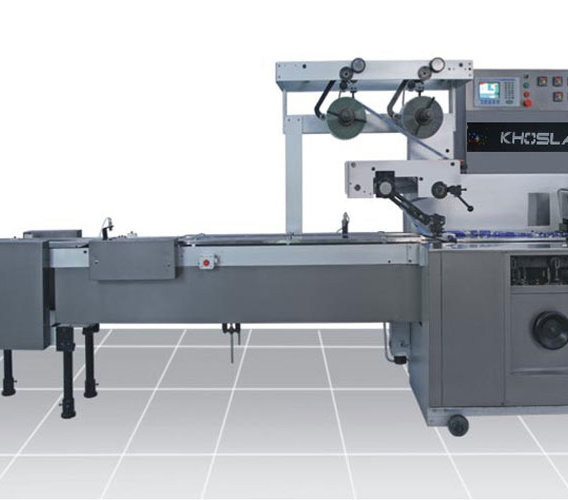

LOGIPAC 22N Machine is designed to give upto 160-170ppm. Smart Conveyor of the machine is a synchronizing conveyor system (using servo drives) to position randomly coming products for entry on the infeed chain conveyor of the main machine. Wrapper is fed through positive pull rollers to relieve pull pressure from the bottom sealers for high speed operation. For high speed, accurate print registration- servo drives are used for wrapper pulling. This enables us to set the cut lengths and time the unit through menu based HMI. For missing tablets wrapper is not wasted.

Standard Feature

1. Accumulator Conveyor with in feed sensor directly linkable to the output conveyor of the noodle line by servo motor.

2. Linking smart belt conveyor with the in feed lug conveyor of the machine.

3. Extended Twin Belt In feed to minimize product damage.

4. Bridge Plate for product transfer.

5. Servo Driven Wrapper Feed Arrangement.

6. Servo Driven Double Cutter Sealing Jaws with No- Product no wrap interlock.

7. Machine Timings Settings on HMI with Recipe Storage, PLC, HMI and servo Drives

from Allen Bradley. (Output speed up to 200ppm – variable)

8. Kubler Slip Rings