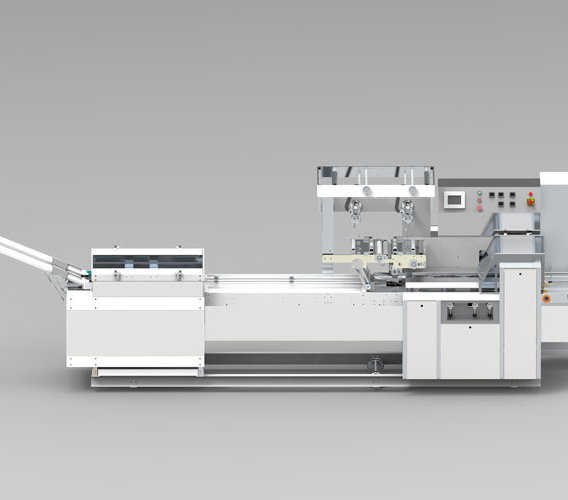

STANDARD FEATURES

» Product loading in ergonomically designed magazines

» All parts in contact with biscuits made of stainless steel or nylon

» Conveyors of the food grade specification

» Collection trays for product powder & crumbs

» Two wrapper spool holders

» ‘Biscuit Trap’ to remove broken biscuits

» Positive drive to wrapper unwind

» Packing date printing at registered position

» AC frequency control drive to infinitely vary speed from 50 to 120 rows per min

» Collator unit for collation from 1 to 4 rows per pack with quick change over

» Additional static heater for long seal

» Pneumatic gussetting

» Fine adjustments of knives and jaw pressure by means of adjusting screws

» 50V supply to heaters for operator’s

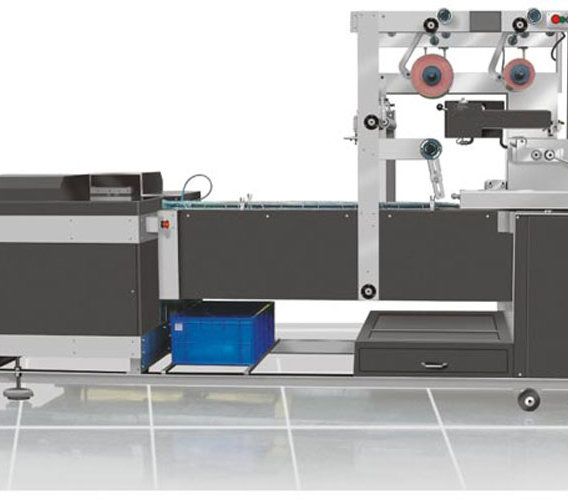

HIGHLIGHT

» Display of speed, shift output and total output

» Trolley wheels

» All variable settings marked on scales for fool proof size change

» Blowing of broken products on in-feed conveyor

» Quick size change over

OPTION:

» High speed

» High productivity

» Fool proof size changeability

» Gentle handling of products

Machine speed upto 120 PPM infinitely variable

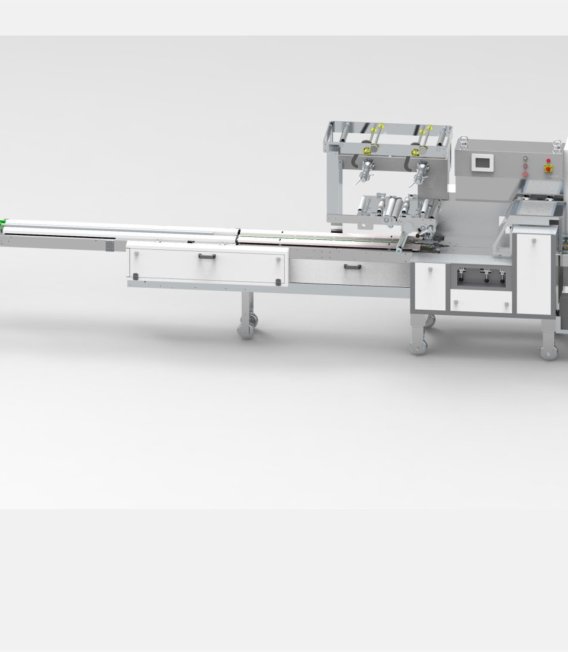

PRODUCT SPECIFICATION

| PRODUCT SIZE (all dimensions in mm) | |||||||||

|

|||||||||

| other dimensions may be considered on request combination of max. sizes may be out of the range of specifications | |||||||||

| WRAPPING MATERIAL WRAPPER : BOPP, BOPP/PE AND OTHER SEALABLE FILMS AND LAMINATES OUTSIDE DIA 400mm CORE DIA 70mmSPEED UPTO 140 PPM INFINITELY VARIABLMACHINE WEIGHT : 2400 Kgs.ELECTRICALS:» SUPPLY VOLTAGE : 3 PHASE 220V, 50HZ » HEATER VOLTAGE : 50 V » HEATER POWER : 3.3 KW » CONTROL VOLTAGE : 24V DC Electric power: 11kW at 3 phase 230 VAC (inclusive of hot melt applicator) AIR CONSUMPTION: 90 LPM at 5 bars |