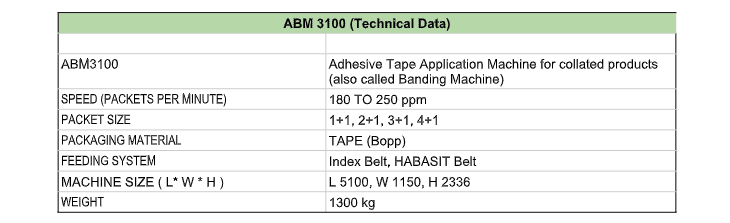

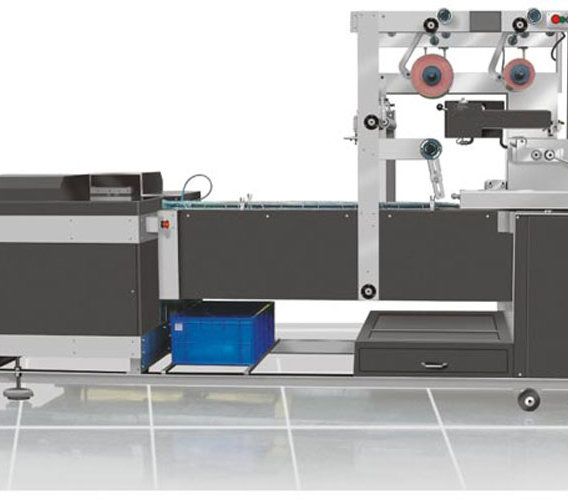

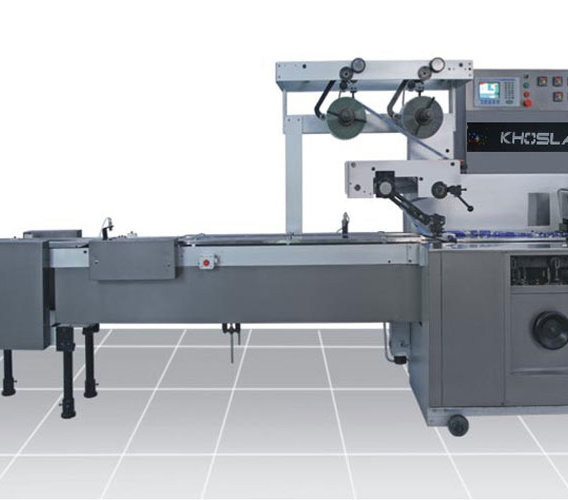

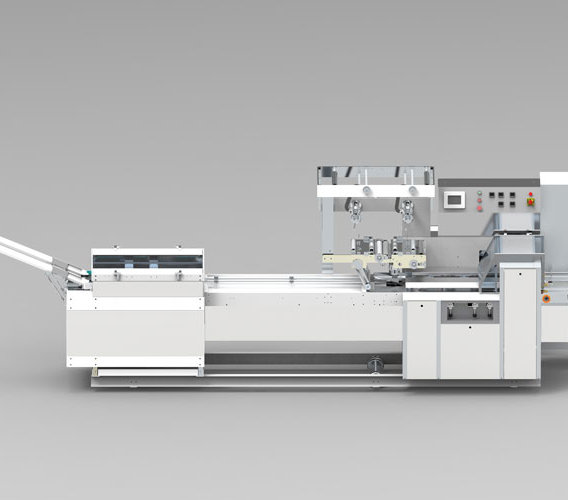

ABM 3100 is an adhesive tape application machine also called banding machine that automatically collates desired number of wrapped soaps in up-right position and then applies printed adhesive tape on both sides. Infeed conveyor of the machine is linked to the discharge belt of the wrapping machine. Product sensors and PLC based logic maintains right amount of queue on the infeed conveyor of the machine. The machine can operate at

high speed (180-250 ppm) to match output speeds of most wrapping machines in direct link-up with it. Design of machine allows easy and fast changeover with minimal change parts.

Highlights

1. Quick change over

2. Full in-line operator free link-up to wrapping machine.

3. Full linkability to soap wrapping machine

Standard Features:

1. Infeed conveyor 1.5m long with independent geared motor drive with speed

adjustment through VFD.

2. PLC/HMI from Rockwell Automation. All critical timings can be done from HMI and

stored (upto 256 recipes) for quick recall.

3. Operator’s control and HMI are on a swiveling pendant to allow the operator to

operate from both sides of the machine.

4. Electrical safety is ensured by physically separating low voltage circuit from the power circuit.

5. Full stainless steel guarding with large polycarbonate view panels and interlocks to provide CAT-2 safety protection to the operator.

6. No-soap-no-band interlock.

7. Web break-machine stop interlock.

8. Pneumatics from Festo.

9. The speed of machine is 180 – 250 PPM

Optional Features:

1. Change parts.

2. Customized infeed conveyor.

3. Tool Kit.

4. Emergency spares kit.

5. MIS for production data of shift available from HMI.