- Two stage servo based infeed conveyor with HMI settings for PLC control.

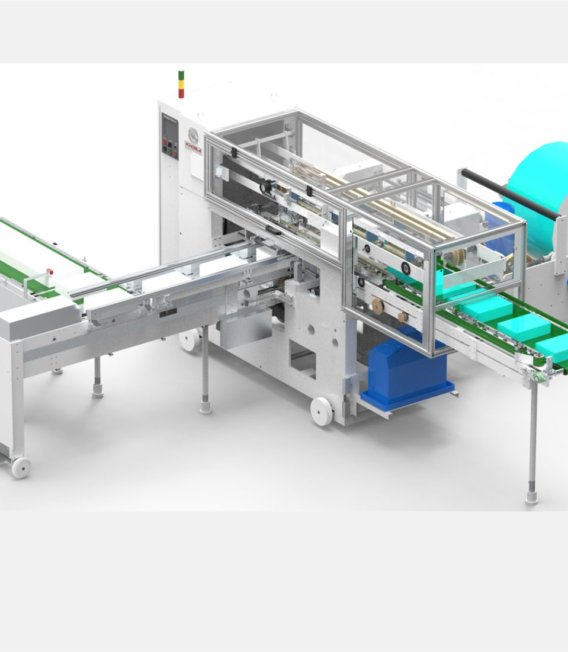

- Continuous motion suction pick & place for high speed operation.

- Auto feed conveyor.

- Four axes servo control with HMI for: fully automatic cut length selection for wrapper and inner card liner, print mark control and overlap control. All settings are done from HMI.

- No-product-no-wrapper interlock, accurate automatic print registration at high speeds.

- Web break interlock.

- Special design discharge end conveyor to minimize skew.

- Self lubrication main mechanical drives.

- Digital temperature controls, Main motor AC Variable speed drive.

- Automatic splicing units for stiffener & wrapper.

- Machine is designed to give up to 230 ppm (machine speed and accuracy is dependent of quality of packing material, soap size and its quality, uniform inflow of the product)

- Heavy distortion free cast structure

- Full safety guarding with electrical interlocks.

- Logging of production output, down time and machine efficiency data for shift-wise production.

- Automation hardware from Rockwell automation.

Optional Features:

- Change parts.

- Tool Kit.

- Emergency Spares Kit.

- Remote diagnostic features.

- Mirror image orientation to allow single operator to run two machines.

- MIS for production data of shift available from HMI.

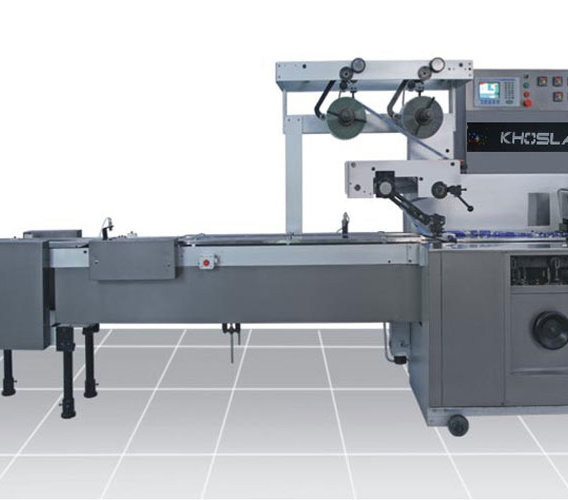

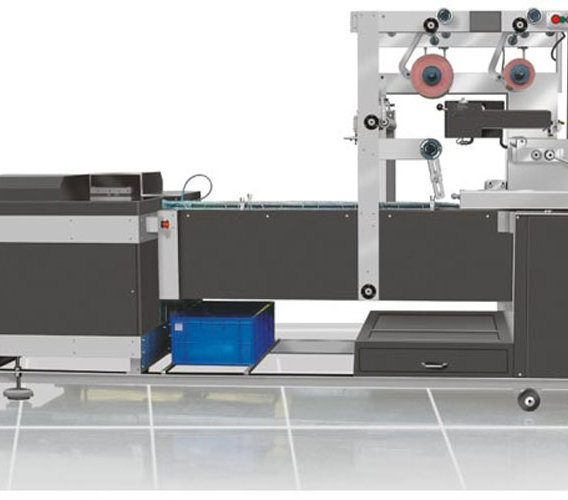

| WRAPPER 8000T | Wrapping Machine |

|---|---|

| Pack Size (L x W x H) | MAX (110 x 65 x 40) MIN (65 x 35 x 13) Note: Other dimensions may be considered on request combination of max. sizes may be out of the range of specifications |

| Line Drawing of the pack |  |

| Wrapping Material | WRAPPER: Paper/Poly / Hotmelt / Lamination Stiffener: Card PAPER / Poly Laminate |

| Maximum Reel Width (Packaging Material Dimension) | 160 mm |

| Maximum Reel Diameter(Packaging Material Dimension) | 600 mm |

| Core Dia of Reel | 76 mm |

| Bare Machine Size (L X W X H) | (4300 x 1035 x 2150) mm |

| Packed Machine Size (L X W X H) | (4700 x 1475 x 2285) mm |

| Bare Machine Weight | 1800 Kgs. Approx. |

| Packed Machine weight | 2400 Kgs. approx. |

| Packed Conveyor Size (L X W X H ) | (2355 x 765 x 1370)mm |

| Bare Conveyor Weight | 366 Kgs. approx. |

| Packed Conveyor Weight | 466 Kgs. approx. |

| Automatic Transfer of the product from Manufacturing Line to Packaging Line | Yes |

| Sub Assy Pictures | |

|

|

The above data is a general guidelines, production speed will depend upon product size and characteristics, proficiency of feeding, and wrapper characteristics. The production speed will also be lower than mechanical speed stated above if one or more factors are close to the range limits.

| Machine Layout- Front View | Floor Layout – Top view |

|

|